PLC vs PAC: Which Control System is Right for Your Smart Factory?

- confia control system

- Dec 19, 2025

- 3 min read

Introduction

In modern manufacturing, choosing the right control system directly impacts uptime, quality, and energy costs. A wrong choice can limit scalability, while the right one can prepare your plant for Industry 4.0 and global competition.

What Is a PLC?

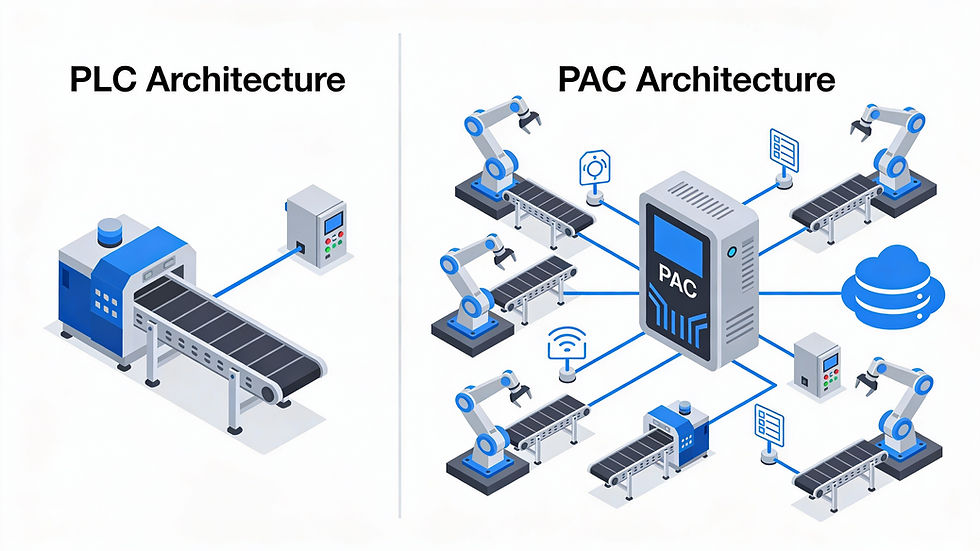

A Programmable Logic Controller (PLC) is a rugged industrial computer designed for reliable, real-time control of machines and processes. PLCs are widely used in assembly lines, packaging machines, conveyor systems, and utility equipment where deterministic, repeatable logic is required.

PLCs execute a scan cycle: read inputs, run the program, and update outputs in milliseconds, making them ideal for tasks like starting motors, reading sensors, and handling safety interlocks. Programming is usually done in ladder logic, which resembles electrical relay diagrams and is easy for technicians to understand.

What Is a PAC?

A Programmable Automation Controller (PAC) combines the robustness of PLCs with the processing power of industrial PCs. PACs are built for complex, data-driven applications such as multi-axis motion control, batch processing, traceability, and integration with MES, ERP, and cloud platforms.

PACs support multiple IEC 61131-3 languages such as ladder logic, structured text, and function block diagrams, allowing engineers to choose the best approach for each task. With more CPU power, memory, and networking options, PACs can handle high-speed I/O, large tag databases, and real-time analytics.

Key Differences Between PLCs and PACs

Aspect | PLC | PAC |

Architecture | Fixed, compact or modular, typically handling smaller I/O counts and dedicated tasks. | Open, modular platform designed for thousands of I/O points and system‑wide integration. |

Programming | Mainly ladder logic and simple function blocks; easy to learn. | Multiple languages (ladder, structured text, FBD, sometimes C/C++), ideal for complex strategies. |

Processing power | Optimized for deterministic logic and basic math. | Higher CPU power and memory for motion control, data logging, and advanced algorithms. |

Connectivity | Basic industrial networks; limited data storage. | Advanced Ethernet, OPC UA, cloud, and database connectivity for Industry 4.0. |

Typical cost | Lower upfront cost; best for simple machines or standalone lines. | Higher investment but better value for complex, integrated plants. |

When to Choose a PLC?

Choose a PLC when you need:

Reliable control of a single machine or a small cell (conveyors, pumps, basic packaging)

Minimal data handling and reporting requirements

A cost-effective solution with simple maintenance for technicians

Explore our range of PLC products from leading brands including Mitsubishi, Siemens, and Delta.

When to Choose a PAC?

Choose a PAC when you need:

High-speed, coordinated control of multiple robots, drives, or production lines

Integration with SCADA systems, MES, ERP, or cloud dashboards for global monitoring

Advanced analytics, traceability, and remote diagnostics across sites

How Confia Helps You Choose the Right Controller

CONFIA CONTROL SYSTEM, part of Shenzhen Confia International Trade Co. Ltd, specializes in sourcing, engineering, and servicing industrial automation hardware from China to factories worldwide.

From PLC-based retrofits to PAC-driven smart manufacturing projects, Confia designs, programs, and commissions complete control solutions, including PLCs, HMIs, drives, SCADA systems, and control panels, with global shipping and remote support.

Confia's PLC and PAC Services:

Global sourcing of PLCs, PACs, HMIs, and drives from leading Chinese and international brands

Custom programming, panel building, and commissioning for brownfield and greenfield plants through our professional services

Consulting and platform integration for Industry 4.0 transformation

Long-term AMC services, retrofitting, and upgrade support to extend asset life and reduce downtime

Field service and remote support available across global locations

Quality control and product inspection for all sourced components

Ready to Upgrade Your Control System?

Whether you need a simple PLC replacement or a comprehensive PAC-based automation solution, Confia has the expertise and global network to deliver. Book a consultation today or contact our engineering team to discuss your project requirements.

Comments